POLISHING

More then 5 years since we started the research of robotic

polishing and more specific into the field of wedding

bands.

During the last years and thanks to our experience, we have

been able to use this technology towards other industries

which are in need to polish, lap, grind, laser engrave, etc…

parts or pieces of different shapes.

Today, we construct the cells upon the need of our customers,

starting from 1 cell up to 2, 3 or 4 aligned cells connected

with each other.

We start from a standard base with a modern design having

security doors, strong suction device with dust collecting,

robotic arm and pressure force controller.

- Reduced cell dimensions

- Buff diameter from 100 to 250 mm

- Miniature brushes starting from Ø 16 mm

- 2 to 5 workstation per cell

- Suction and dust collection/filtering

- Illumination by LED’s

- Pressure force controller

- Rotating centre for work pieces

- Liquid or solid polishing paste

- Buff cleaning devices

- Workpiece cleaning by ultrasonic/steam

- Work piece drying center

- Automatic replacement of miniature brushes

- Staübli Robot TX60-60L

- PC control of programmed parameters

- Loading/unloading center

- Transfer between multiple cells

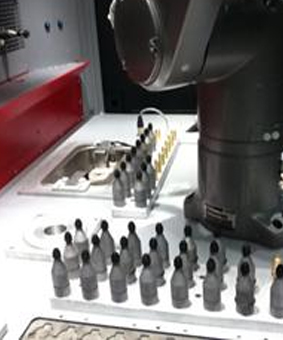

Stock up center for holders of miniature brushes.

These special quick-change holders are replaced on the machine

by the robot.

Next, depending of the need of our customer, we add working

stations and accessories.

Robotic polishing cells do not only increase your productivity

, but it helps you to keep up with your needed final quality

without being dependant of individuals.

It is our task to work out, together with the customer, the

cell in order to achieve the desired final quality.

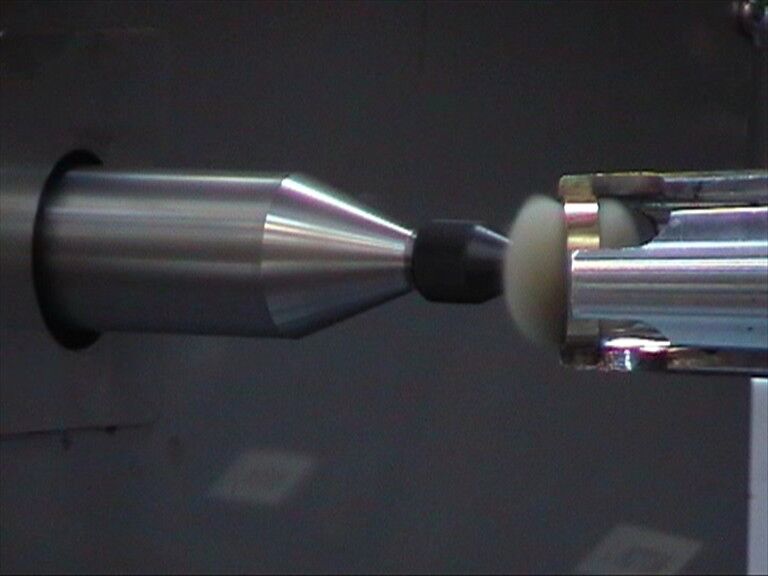

Feeding solid polishing paste, diam. 40 mm on a buff.

System equipped with a buff cleaning device

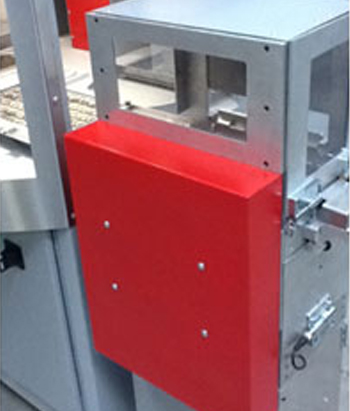

Vertical loading and unloading device for product pallets.

The standard device can keep upto 10 pallets, having 60

positions each.

Each pallet can be coded to launch a specific program.

2 polishing cells connected by a transfer to increase productivity speed

Applications

- MECHANICAL PIECES

- WATCH- AND JEWELRY ITEMS

- ELECTRONICS